Description

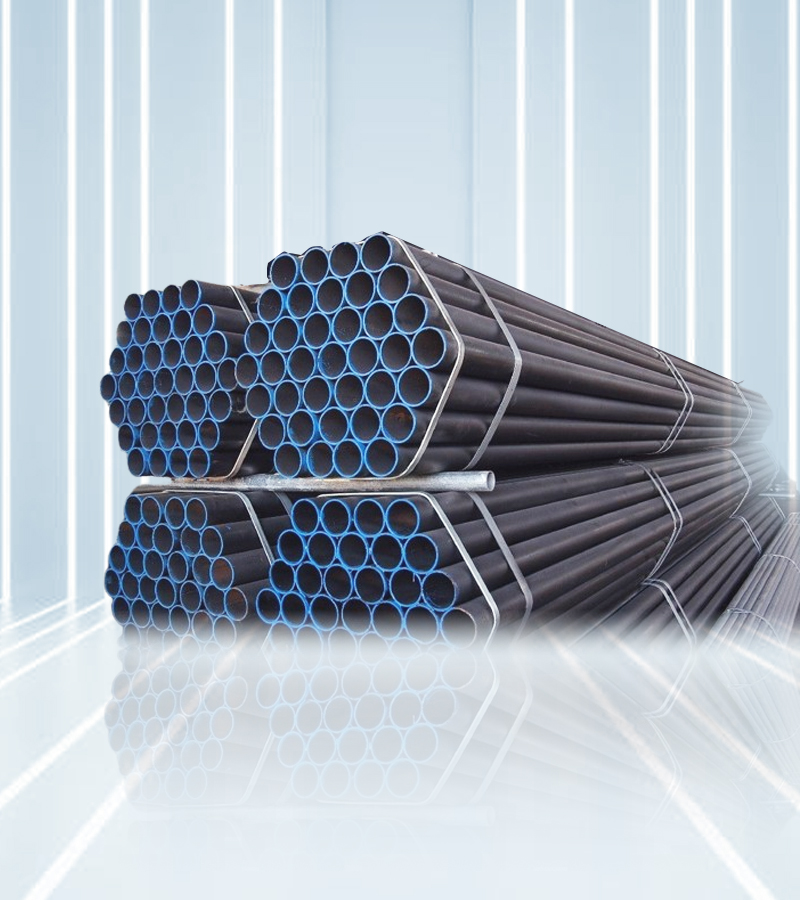

Seamless and ERW pipes are integral components in piping systems, offering reliability, efficiency, and versatility in transporting fluids, gases, and materials across various industries. Engineered with precision manufacturing techniques, Seamless and ERW pipes feature seamless construction and tight dimensional tolerances, ensuring smooth flow and optimal performance in critical applications.

Seamless pipes are manufactured through a process that involves extruding a solid billet through a die to form a cylindrical shape without any seams or welds. This seamless construction eliminates weak points and ensures uniformity in material properties, making Seamless pipes ideal for high-pressure and high-temperature applications where integrity and reliability are paramount. ERW (Electric Resistance Welded) pipes are produced by forming flat steel strips into cylindrical shapes and welding the longitudinal seam using electric resistance welding techniques. While ERW pipes may have a visible weld line along the length, they offer excellent dimensional accuracy and consistency, making them suitable for a wide range of industrial applications.

Both Seamless and ERW pipes are available in various materials such as carbon steel, stainless steel, and alloy steel, offering flexibility to meet specific project requirements. With their corrosion resistance, durability, and strength, Seamless and ERW pipes are widely used in industries such as manufacturing, oil and gas, construction, automotive, and aerospace. Whether you need seamless flow for high-pressure fluid transfer or cost-effective solutions for general-purpose piping, our Seamless and ERW pipes provide the reliability, performance, and versatility to meet your diverse application needs with confidence.

Benefits

- Seamless Flow: Seamless and ERW pipes ensure smooth and uninterrupted flow of fluids, gases, and materials, minimizing turbulence and pressure drop in piping systems.

- High Strength: Engineered for durability, Seamless and ERW pipes offer high tensile strength and resistance to bending and deformation, ensuring reliable performance in demanding applications.

- Corrosion Resistance: Crafted from premium materials such as carbon steel, stainless steel, or alloy steel, these pipes provide exceptional corrosion resistance, extending service life and reducing maintenance costs.

- Leak-Free Performance: With their precision manufacturing and tight tolerances, Seamless and ERW pipes offer leak-free performance, preventing costly leaks, spills, and downtime in industrial operations.

- Versatility: Available in various sizes, grades, and specifications, Seamless and ERW pipes are versatile solutions suitable for a wide range of applications across industries.

Technology

- Seamless Construction: Seamless pipes are manufactured without any seams or welds, ensuring uniformity in material properties and eliminating weak points in the pipe structure.

- Electric Resistance Welding (ERW): ERW pipes are produced by welding the longitudinal seam using electric resistance welding techniques, resulting in a strong and reliable bond.

- Heat Treatment: Both Seamless and ERW pipes can undergo heat treatment processes such as annealing, quenching, and tempering to enhance their mechanical properties and microstructure.

- Non-Destructive Testing (NDT): Advanced NDT techniques such as ultrasonic testing and radiographic inspection are used to ensure the quality and integrity of Seamless and ERW pipes.

- Precision Manufacturing: Seamless and ERW pipes are manufactured with precision engineering and quality control measures to meet stringent industry standards and specifications.

Reliability

- Consistent Performance: Seamless and ERW pipes deliver consistent performance and reliability, meeting the demands of critical applications in various industries.

- Quality Assurance: Manufactured to strict quality standards and subjected to rigorous testing, Seamless and ERW pipes undergo thorough inspection to ensure compliance with industry requirements.

- Long Service Life: With their corrosion resistance, durability, and strength, Seamless and ERW pipes offer long service life, minimizing the need for frequent replacements and repairs.

- Proven Track Record: Seamless and ERW pipes have a proven track record of reliability and success in numerous projects and applications worldwide, demonstrating their dependability and effectiveness.

- Material Certification: Material certifications and traceability are provided for Seamless and ERW pipes, ensuring transparency and confidence in their quality and performance.