Description

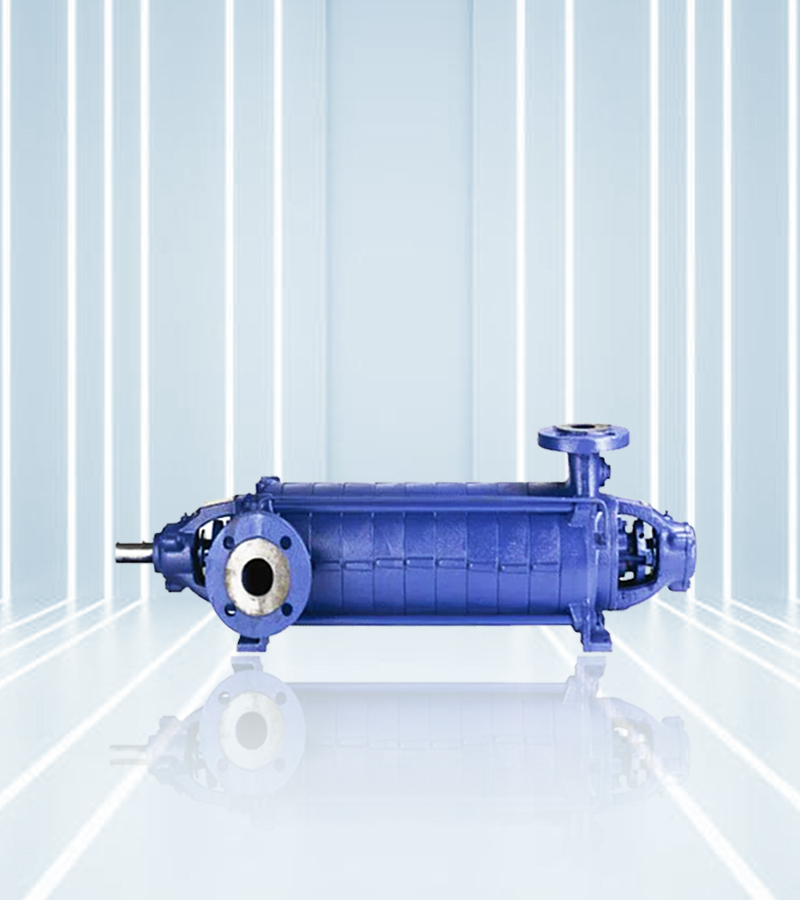

Horizontal Multistage and Vertical Multistage pumps are versatile and efficient pumping solutions designed to deliver high-pressure fluid transfer in a wide range of applications. These pumps feature multiple impellers arranged in series, allowing for gradual pressure buildup and efficient energy transfer, resulting in consistent and reliable performance. Horizontal Multistage pumps are typically installed horizontally, offering space-saving solutions and ease of maintenance in industrial and commercial settings. They are commonly used for boosting water pressure in buildings, circulating cooling water in HVAC systems, and transferring fluids in various process industries.

Vertical Multistage pumps, on the other hand, are installed vertically, making them suitable for applications where space is limited or where pumping from deep wells or reservoirs is required. They are commonly used in high-rise buildings, water supply systems, irrigation, and groundwater extraction. Both Horizontal and Vertical Multistage pumps offer several advantages, including high efficiency, low maintenance requirements, and robust construction. They are designed to handle a wide range of fluids, including clean water, chemicals, and corrosive liquids, making them suitable for diverse industrial, commercial, and municipal applications.

With their multi-stage design, these pumps provide uniform and steady flow rates, ensuring consistent performance even under varying operating conditions. They are engineered with high-quality materials and precision manufacturing techniques to withstand the rigors of continuous operation and harsh environments. Whether you need horizontal installation for compact spaces or vertical installation for deep well pumping, our Multistage pumps offer the versatility, efficiency, and reliability to meet your fluid handling needs with confidence.

Benefits

- High Pressure Capability: Horizontal and Vertical Multistage pumps are capable of generating high pressures, making them ideal for applications requiring elevated water pressure, such as irrigation, water supply, and firefighting.

- Energy Efficiency: With their multi-stage design, these pumps offer efficient energy transfer, minimizing power consumption and reducing operating costs over the long term.

- Versatility: Horizontal and Vertical Multistage pumps are versatile solutions suitable for a wide range of applications, including industrial processes, commercial buildings, municipal water systems, and agricultural irrigation.

- Compact Design: Horizontal Multistage pumps offer space-saving solutions with their horizontal installation, while Vertical Multistage pumps are well-suited for applications with limited space due to their vertical configuration.

- Reliable Performance: Engineered for durability and longevity, these pumps provide reliable and consistent performance, ensuring uninterrupted operation and minimal downtime in critical applications.

Technology

- Multi-Stage Impellers: Horizontal and Vertical Multistage pumps feature multiple impellers arranged in series, allowing for gradual pressure buildup and efficient energy transfer.

- Balanced Shaft Design: These pumps utilize balanced shaft designs to minimize vibration and ensure smooth operation, reducing wear and tear on components and extending pump life.

- Precision Engineering: Manufactured with precision engineering techniques, Horizontal and Vertical Multistage pumps undergo rigorous testing to meet strict performance and reliability standards.

- Variable Speed Control: Some models offer variable speed control options, allowing for precise flow rate adjustment to meet changing system demands and optimize energy efficiency.

- Advanced Materials: These pumps are constructed from high-quality materials such as stainless steel, cast iron, and bronze, providing corrosion resistance and durability in harsh environments.

Reliability

- Robust Construction: Horizontal and Vertical Multistage pumps are built to withstand the rigors of continuous operation, featuring robust construction and durable components.

- Sealed Bearings: Sealed bearings are used to protect internal components from contamination and ensure smooth operation, enhancing pump reliability and longevity.

- Low Maintenance Requirements: With their efficient design and high-quality materials, these pumps require minimal maintenance, reducing downtime and maintenance costs over the pump’s lifespan.

- Overload Protection: Some models are equipped with overload protection features such as thermal overload protection or automatic shutdown mechanisms to prevent damage from overloading.

- Industry Standards Compliance: Horizontal and Vertical Multistage pumps comply with industry standards and regulations for performance, safety, and reliability, providing peace of mind to users.