In industrial settings where explosive gases, dust, or flammable materials are present, ensuring the safety of electrical equipment is paramount. Flameproof motors, also known as explosion-proof motors, are specially designed to operate safely in such hazardous environments

What Are Flameproof Motors?

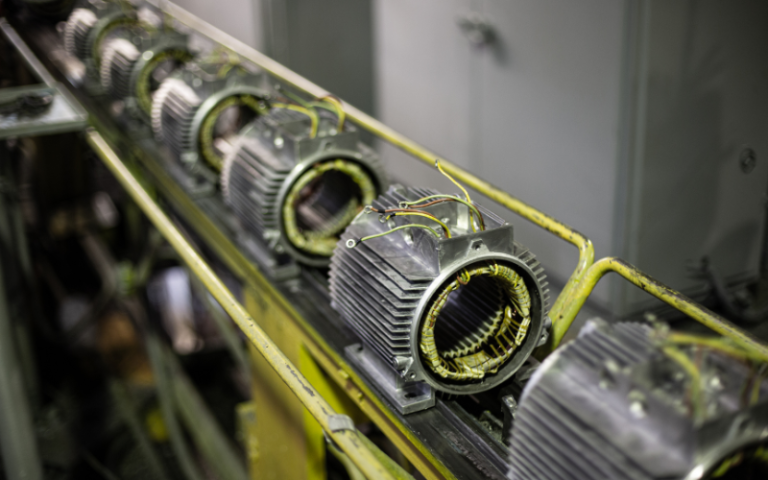

Flameproof motors are electric motors specifically engineered to prevent the ignition of surrounding explosive atmospheres. They are constructed to contain any internal explosion and prevent it from escaping and igniting external gases or dust. These motors are certified to meet stringent international safety standards, ensuring they provide reliable performance without compromising safety.

Key Features of Flameproof Motors

Robust Construction: Flameproof motors are built with heavy-duty enclosures that can withstand internal explosions and prevent the escape of flames or hot gases. The enclosures are typically made of cast iron or other durable materials.

Sealed Design: All components, including wiring and terminal boxes, are sealed to prevent the entry of hazardous substances and to contain any internal explosion.

Temperature Control: These motors are designed to operate at lower temperatures to avoid igniting flammable substances. They often include temperature sensors and cooling systems to maintain safe operating conditions.

Certification and Compliance: Flameproof motors are certified by international standards organizations such as ATEX (Atmospheres Explosibles) and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). These certifications ensure that the motors meet the necessary safety requirements.

Benefits of Using Flameproof Motors

1. Enhanced Safety

The primary benefit of flameproof motors is the enhanced safety they provide in hazardous environments. By containing internal explosions and preventing external ignition, they significantly reduce the risk of fires and explosions.

2. Regulatory Compliance

Using flameproof motors ensures compliance with international safety regulations, which is crucial for operating in industries where hazardous materials are present. This compliance helps avoid legal issues and potential fines.

3. Reliability and Durability

Flameproof motors are designed for reliability and durability in harsh conditions. Their robust construction and high-quality components ensure long-term performance with minimal maintenance.

4. Versatility

These motors are available in various sizes and power ratings, making them suitable for a wide range of applications. They can be used in different hazardous zones, including areas with flammable gases, dust, and fibers.

Common Applications of Flameproof Motors

Flameproof motors are used in numerous industries where safety is a top priority due to the presence of hazardous substances. Here are some common applications:

1. Oil and Gas Industry

In the oil and gas industry, flameproof motors are essential for operating equipment such as pumps, compressors, and drilling machines. They are used in both onshore and offshore facilities, where explosive gases are often present.

2. Chemical and Petrochemical Plants

Chemical and petrochemical plants handle a variety of flammable and explosive substances. Flameproof motors are used to power mixers, agitators, and conveyors, ensuring safe operation in these volatile environments.

3. Mining Industry

The mining industry involves the extraction and processing of minerals, often in dusty and potentially explosive atmospheres. Flameproof motors are used in mining equipment, ventilation systems, and conveyors to maintain safety and reliability.

4. Pharmaceutical Industry

In pharmaceutical manufacturing, flameproof motors are used in processes that involve flammable solvents and dust. They ensure safe operation of mixers, blenders, and processing equipment.

5. Food and Beverage Industry

Certain processes in the food and beverage industry generate flammable dust or gases. Flameproof motors are used in milling, grinding, and mixing equipment to prevent ignition and ensure safe production.

6. Textile Industry

The textile industry can produce combustible fibers and dust. Flameproof motors are used in machinery such as looms, spinning machines, and dryers to maintain safety in the production environment.

Conclusion

Flameproof motors are crucial for ensuring safety in hazardous environments where explosive gases, dust, or flammable materials are present. Their robust construction, sealed design, temperature control, and compliance with international standards make them an essential component in many industries. By using flameproof motors, businesses can enhance safety, ensure regulatory compliance, and maintain reliable and durable operations.