In today's industrial world, energy efficiency and sustainability are more important than ever. Among the various types of motors used in industries, IE2 motors stand out for their energy efficiency and reliability. Whether you're an engineer, a plant manager, or simply someone interested in industrial machinery, understanding IE2 motors can help you make informed decisions for your operations.

What Are IE2 Motors?

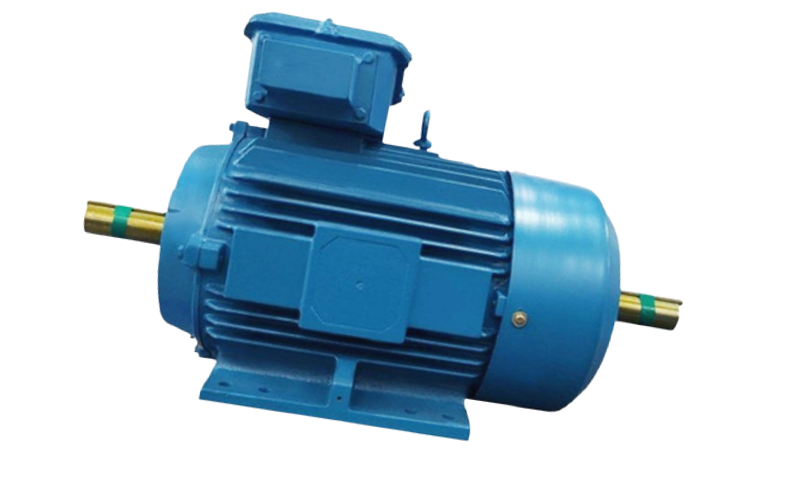

IE2 motors are electric motors that meet the IE2 efficiency class as defined by the International Electrotechnical Commission (IEC). The IEC sets global standards for electric motors, ensuring that they meet specific performance and efficiency criteria. IE2 stands for "International Efficiency," and motors classified under this category offer higher energy efficiency compared to IE1 motors, which are the baseline standard.

Key Features of IE2 Motors

Energy Efficiency: IE2 motors are designed to consume less energy while providing the same output as less efficient motors. This leads to significant cost savings on energy bills, especially in applications where motors run continuously.

Durability and Reliability: Built with high-quality materials and advanced engineering, IE2 motors are known for their robustness and long operational life. They require less maintenance and experience fewer breakdowns, which translates to lower downtime for industrial operations.

Compliance with Regulations: Many countries have stringent regulations regarding energy consumption and efficiency. IE2 motors comply with these regulations, making them a suitable choice for industries aiming to meet legal requirements and reduce their carbon footprint.

Versatility: IE2 motors come in a wide range of sizes and power ratings, making them suitable for various industrial applications, from pumps and fans to conveyors and compressors.

Benefits of Using IE2 Motors

1.Cost Savings

One of the most significant advantages of IE2 motors is the cost savings they offer. By reducing energy consumption, these motors lower electricity bills. Over time, the savings can offset the initial investment in IE2 motors, making them a cost-effective solution in the long run.

2. Environmental Impact

IE2 motors help reduce greenhouse gas emissions by consuming less power. This makes them an environmentally friendly option, aligning with global efforts to combat climate change and reduce industrial pollution.

3. Improved Performance

The advanced technology used in IE2 motors results in better performance, with smoother operation and less noise. This can enhance the overall efficiency and productivity of industrial processes.

4. Regulatory Compliance

Using IE2 motors ensures compliance with international energy efficiency standards. This is particularly important for businesses operating in regions with strict energy regulations, avoiding potential fines and legal issues.

Applications of IE2 Motors

IE2 motors are used across a wide range of industries due to their versatility and efficiency. Some common applications include:

- Pumps: In water treatment plants, agricultural irrigation systems, and HVAC systems.

- Fans and Blowers: In ventilation systems, industrial cooling, and air handling units.

- Compressors: In refrigeration, air conditioning systems, and manufacturing processes.

- Conveyors: In material handling, packaging industries, and logistics operations.

- Machine Tools: In manufacturing plants, automotive industries, and metalworking.

Choosing the Right IE2 Motor

When selecting an IE2 motor, consider the following factors:

- Power Requirements: Determine the power needs of your application to choose a motor with the appropriate power rating.

- Environmental Conditions: Consider the operating environment, including temperature, humidity, and exposure to corrosive substances.

- Load Characteristics: Understand the load characteristics of your application to select a motor that can handle the required torque and speed.

- Efficiency Class: Ensure the motor meets the IE2 efficiency standards to guarantee energy savings and compliance.

Conclusion

IE2 motors represent a significant advancement in energy-efficient motor technology. Their ability to reduce energy consumption, improve performance, and comply with international regulations makes them an excellent choice for various industrial applications. By investing in IE2 motors, businesses can achieve substantial cost savings, enhance operational efficiency, and contribute to a greener planet.

If you're considering upgrading your industrial equipment, IE2 motors are worth exploring. With their myriad benefits and wide range of applications, they can play a crucial role in optimizing your operations and driving sustainability efforts.